~If it doesn’t work even if you pull it, try pushing it~

Roll-to-roll type screen printers are highly productive because they print while the film is being conveyed continuously.

Substrates, touch panels, etc. are mass-produced with this type of equipment.

Substrates, touch panels, etc. are mass-produced with this type of equipment.

Suction rollers are often used when conveying film in this device.

Adsorption roller vacuum-adsorbs the film and feeds it.

General film does not allow air to pass through, so if the air inside the suction roller is removed,

The film can be adsorbed and fixed at atmospheric pressure.

Adsorption roller vacuum-adsorbs the film and feeds it.

General film does not allow air to pass through, so if the air inside the suction roller is removed,

The film can be adsorbed and fixed at atmospheric pressure.

However, this method assumes that the film to be conveyed is "impermeable to air".

"Breathable" films cannot be transported.

"Breathable" films cannot be transported.

So how do you transport "breathable" film?

For example, carbon paper, which is a porous conductive paper (e.g. paper made of graphitized carbon fibers)

such as printing to

For example, carbon paper, which is a porous conductive paper (e.g. paper made of graphitized carbon fibers)

such as printing to

One day, Mr. M was brooding over this matter in front of the printing press.

Even if the carbon paper was placed on the suction roller as it was, air leaked out and it did not stick.

It was useless even if the suction power was strengthened.

However, when I put the polyester film I happened to have in my hand on the carbon paper,

The carbon paper was firmly attached to the suction roller.

Since the carbon paper was sandwiched between the polyester film and the suction roller,

It was attracted to the suction roller together with the polyester film.

Carbon paper is not adsorbed as it is, but polyester film

was adsorbed in the form of being pushed. It's exactly the idea of "If pulling doesn't work, try pushing."

Even if the carbon paper was placed on the suction roller as it was, air leaked out and it did not stick.

It was useless even if the suction power was strengthened.

However, when I put the polyester film I happened to have in my hand on the carbon paper,

The carbon paper was firmly attached to the suction roller.

Since the carbon paper was sandwiched between the polyester film and the suction roller,

It was attracted to the suction roller together with the polyester film.

Carbon paper is not adsorbed as it is, but polyester film

was adsorbed in the form of being pushed. It's exactly the idea of "If pulling doesn't work, try pushing."

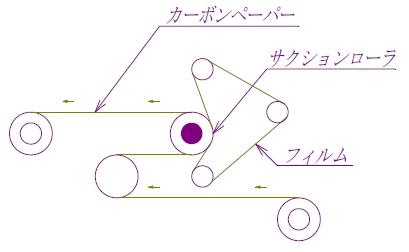

Therefore, Mr. M came up with the transport device shown in the figure below.

The film is sent in sync with the flow of the carbon paper so that the film hits the adsorption part.

The film is looped so it can be used repeatedly.

The film is sent in sync with the flow of the carbon paper so that the film hits the adsorption part.

The film is looped so it can be used repeatedly.

Reference material Patent No. 5411602