~ Examining the stretching direction of the screen version ~

Strain gauges can be used to determine the magnitude and direction of strain.

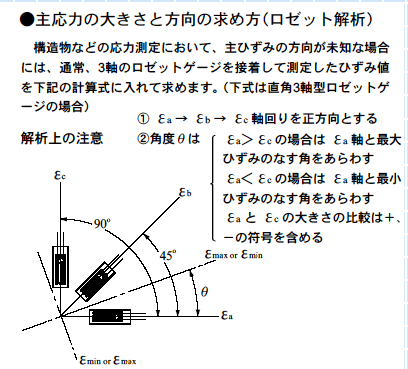

The method of finding the direction from strain gauges is called rosette analysis.

Photo 1

Description 1

A 3-axis strain gauge is used to perform rosette analysis.

As shown in Photo 1, this was pasted on the screen plate and printed, and the direction of elongation of the screen plate was examined.

Specialized software for rosette analysis calculations is available from the manufacturer, so using this software, you can check the direction of stress in real time.

As shown in Photo 1, this was pasted on the screen plate and printed, and the direction of elongation of the screen plate was examined.

Specialized software for rosette analysis calculations is available from the manufacturer, so using this software, you can check the direction of stress in real time.

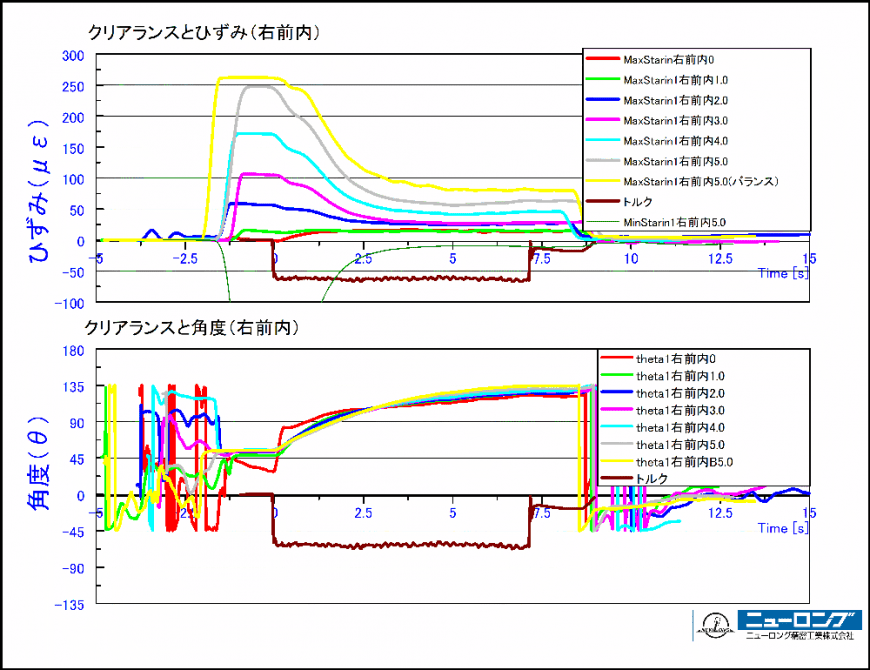

Fig. 1 shows the measurement results.

Figure 1

This is difficult to understand, so Figures 2 and 3 illustrate this in an easy-to-understand manner.

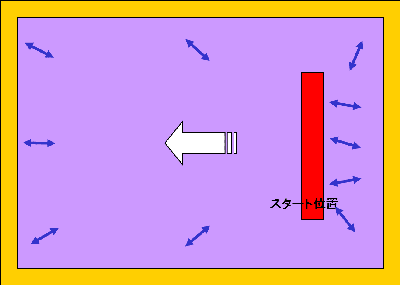

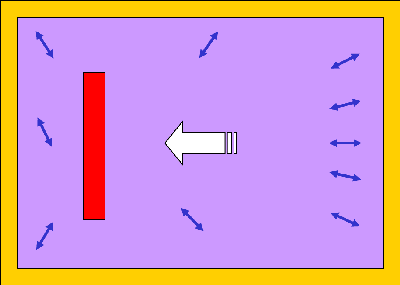

Fig. 2 shows the stencil extension direction immediately after the squeegee (red part) descends and the stroke starts. It can be seen that the plate near the squeegee extends in the stroke direction of the squeegee, while the portion away from the squeegee extends toward the squeegee.

......

Figure 2

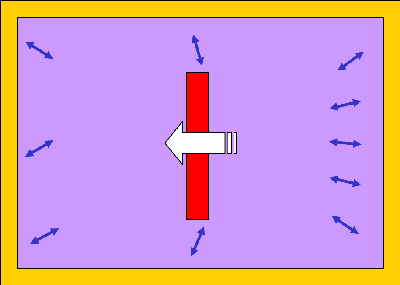

Fig. 3 shows the extension direction of the plate when the squeegee passes through the center of the plate.

You can see that the plate stretches toward the squeegee.

You can see that the plate stretches toward the squeegee.

Figure 3

Fig. 4 shows the plate extension direction just before the squeegee completes its stroke.

The stencil stretches toward the squeegee, but the stretching direction of part ① is different from that shown in Fig. 3. From these results, it is thought that the pattern at the center of the plate moves to the squeegee stroke start side immediately after the squeegee stroke starts, and moves to the squeegee stroke end side just before the squeegee stroke ends.

The stencil stretches toward the squeegee, but the stretching direction of part ① is different from that shown in Fig. 3. From these results, it is thought that the pattern at the center of the plate moves to the squeegee stroke start side immediately after the squeegee stroke starts, and moves to the squeegee stroke end side just before the squeegee stroke ends.

① 、① 、① 、① 、① 、① 、

Figure 4