~ Concept of printing film thickness ~

This time it's a story for screen printing beginners.

Screen printing can form high-definition patterns with simple equipment.

Therefore, we receive inquiries from customers in various fields.

Most of them are related to setting conditions for printing film thickness.

"What should I do to print thickly?"

The contents are such as "To what extent can the printing film thickness be controlled by changing the conditions of the printing press?"

Screen printing can form high-definition patterns with simple equipment.

Therefore, we receive inquiries from customers in various fields.

Most of them are related to setting conditions for printing film thickness.

"What should I do to print thickly?"

The contents are such as "To what extent can the printing film thickness be controlled by changing the conditions of the printing press?"

There are "screen mesh", "thickness of gauze", "thickness of emulsion", "opening ratio", etc. for setting conditions of printing film thickness.

Because these are industry terms, it is difficult to understand for those who have no experience with screen printing.

What is obvious to those familiar with screen printing is not to others.

If you can't explain these well, you will feel that screen printing is rather difficult.

Therefore, using familiar "rice" and "rice", we asked about the conditions of the printing film thickness of screen printing.

I tried to see if I could explain it easily.

(Our factory is located in Minamiuonuma City, Niigata Prefecture, and Koshihikari rice from Minamiuonuma is a representative specialty product.)

Because these are industry terms, it is difficult to understand for those who have no experience with screen printing.

What is obvious to those familiar with screen printing is not to others.

If you can't explain these well, you will feel that screen printing is rather difficult.

Therefore, using familiar "rice" and "rice", we asked about the conditions of the printing film thickness of screen printing.

I tried to see if I could explain it easily.

(Our factory is located in Minamiuonuma City, Niigata Prefecture, and Koshihikari rice from Minamiuonuma is a representative specialty product.)

If you explain the relationship between the specifications of the screen plate and the printing film thickness with "rice"...

Screen plate specifications affect the film thickness of the printed pattern.

Screen plate specifications include "number of meshes", "linearity", "thickness" and "open area ratio".

Let's compare this with rice and a measuring cup.

Screen plate specifications include "number of meshes", "linearity", "thickness" and "open area ratio".

Let's compare this with rice and a measuring cup.

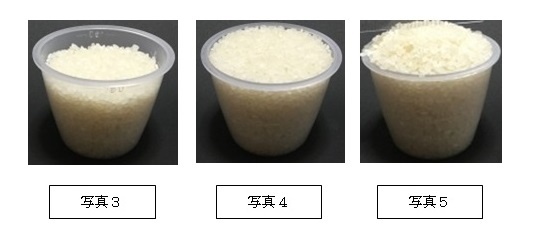

If you want to cook a lot of rice, you will need a lot of rice, so use a large measuring cup to measure the rice.

Also, when cooking a small amount of rice, a small measuring cup is sufficient.

Increasing the thickness of the printed film in screen printing means applying a lot of ink,

As in the previous example, you will need a large measuring cup.

Also, when cooking a small amount of rice, a small measuring cup is sufficient.

Increasing the thickness of the printed film in screen printing means applying a lot of ink,

As in the previous example, you will need a large measuring cup.

The screen version is equivalent to the measuring cup.

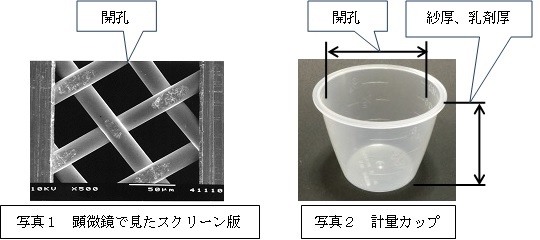

The screen version is shown in Photo 1 and consists of a net called "sa".

The holes in this mesh are called "apertures", and the ink passes through the holes and is transferred.

The opening is the mouth of the measuring cup in Photo 2, and the wider the opening, the easier it is for the ink to pass through.

The thickness of the screen plate, the thickness of the gauze, corresponds to the height of the measuring cup.

The higher it is, the more ink is transferred, resulting in a thicker print film.

The screen version is shown in Photo 1 and consists of a net called "sa".

The holes in this mesh are called "apertures", and the ink passes through the holes and is transferred.

The opening is the mouth of the measuring cup in Photo 2, and the wider the opening, the easier it is for the ink to pass through.

The thickness of the screen plate, the thickness of the gauze, corresponds to the height of the measuring cup.

The higher it is, the more ink is transferred, resulting in a thicker print film.

In order to control the printing film thickness, it is important to consider the specifications of the screen plate.

If you explain the relationship between ink viscosity and print film thickness with rice and rice...

The viscosity of the ink also affects the print film thickness, but let's compare this with rice.

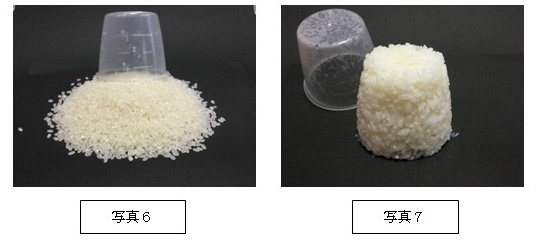

When the measuring cup with rice is turned upside down and the cup is lifted,

As shown in photo 6, you can see that the rice spreads horizontally.

This spread of rice causes blurring in screen printing, and the printing film thickness becomes thinner.

When the measuring cup with rice is turned upside down and the cup is lifted,

As shown in photo 6, you can see that the rice spreads horizontally.

This spread of rice causes blurring in screen printing, and the printing film thickness becomes thinner.

Put the rice cooked in the same way and remove the cup, it will look like Photo 7,

Because the rice is sticky, it formed lumps that were almost the same shape as the cup.

Since rice hardly spreads, the spread of ink (blurring) after printing is small in screen printing.

The print film thickness will be thicker.

Because the rice is sticky, it formed lumps that were almost the same shape as the cup.

Since rice hardly spreads, the spread of ink (blurring) after printing is small in screen printing.

The print film thickness will be thicker.

This causes a difference in ink viscosity in screen printing, and the print film thickness changes.

This time, I talked about the printing film thickness of screen printing, using familiar rice as an example.

Could you explain a little easier to understand?