-Understand the structure of the printing press when setting the conditions for the plate release device-

In screen printing, plate release during printing is important.

When using high-viscosity ink, the amount of clearance alone cannot control plate separation during printing.

In response to this, many screen printers with a function to assist plate separation are on the market.

When using high-viscosity ink, the amount of clearance alone cannot control plate separation during printing.

In response to this, many screen printers with a function to assist plate separation are on the market.

Well, how are the condition settings for the stencil release device?

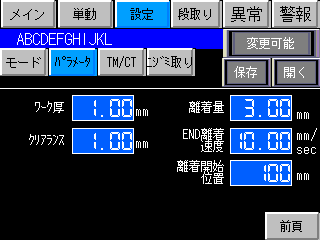

Photo 1 below is a condition setting screen for the plate release device of our typical screen printing machine.

As I wrote in a past column, we call plate separation "detachment", so in our screen printing machine, the condition of the amount of plate separation is called "detachment amount".

Photo 1 below is a condition setting screen for the plate release device of our typical screen printing machine.

As I wrote in a past column, we call plate separation "detachment", so in our screen printing machine, the condition of the amount of plate separation is called "detachment amount".

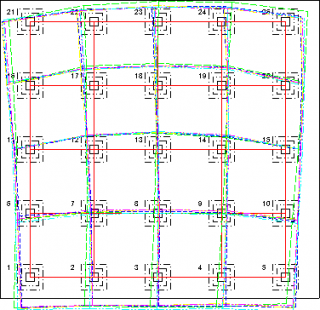

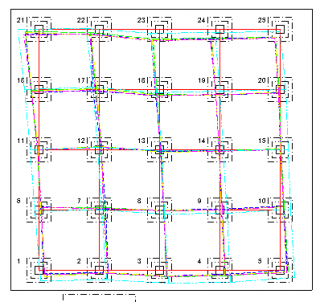

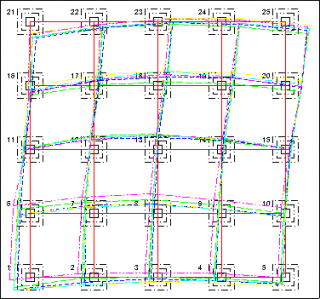

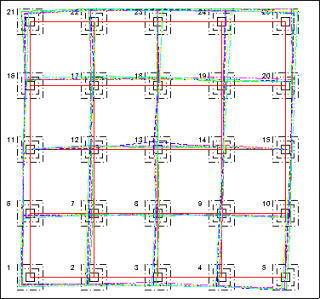

Photo 1

The figure below shows the measurements of the dimensions of the printed pattern after setting the numerical value of "3.00 mm of release/attachment distance" displayed on this screen to printing machines with different structures (A to D).

This shows how much the printed pattern stretched compared to the design value (red line).

This shows how much the printed pattern stretched compared to the design value (red line).

In this way, it can be seen that even if the same detachment amount is set, there is a difference in the expansion and contraction of the printed pattern due to the difference in the structure of the printing machine.

When using the plate release device, it is necessary to understand the structure of the screen printer.

When using the plate release device, it is necessary to understand the structure of the screen printer.